Progress

Report

2024

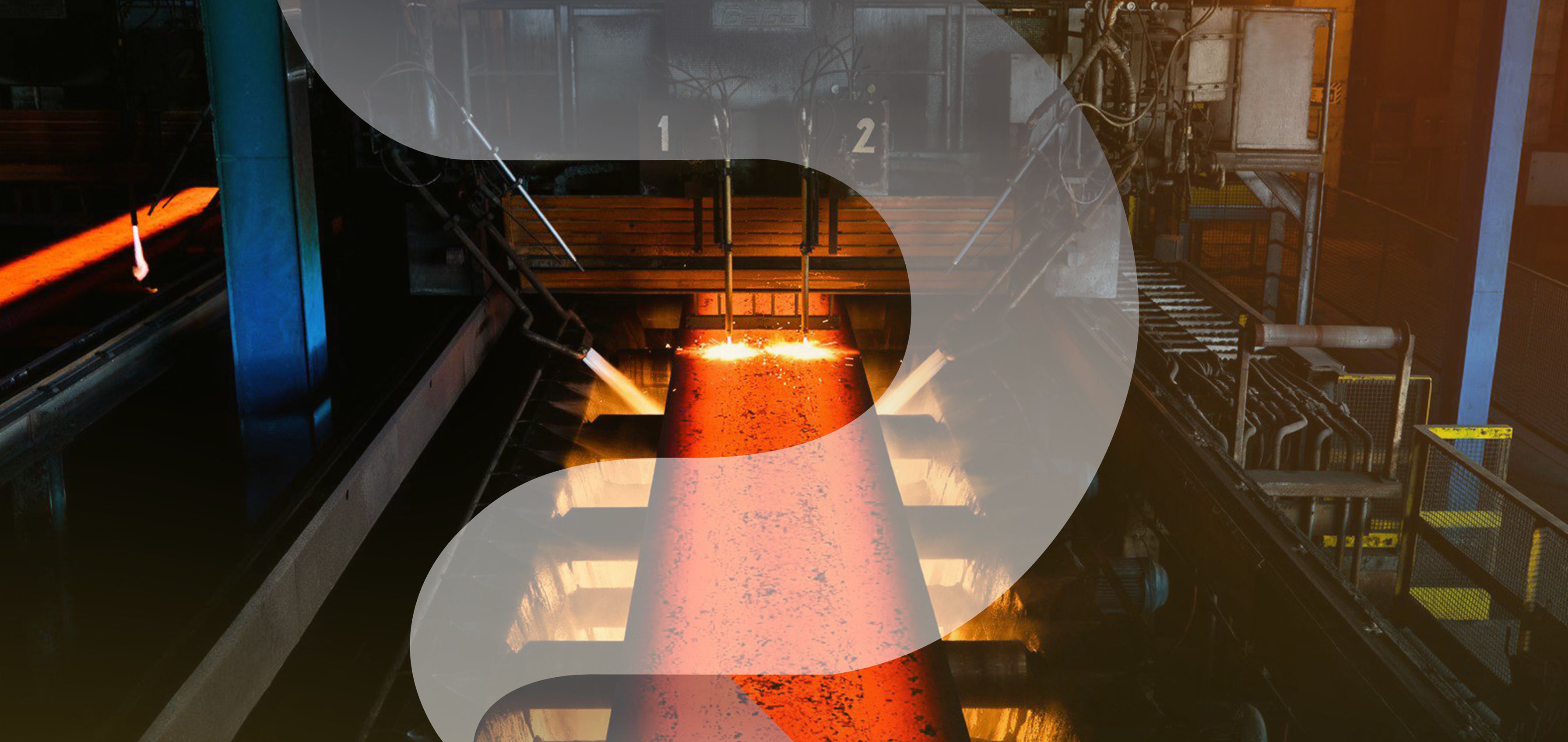

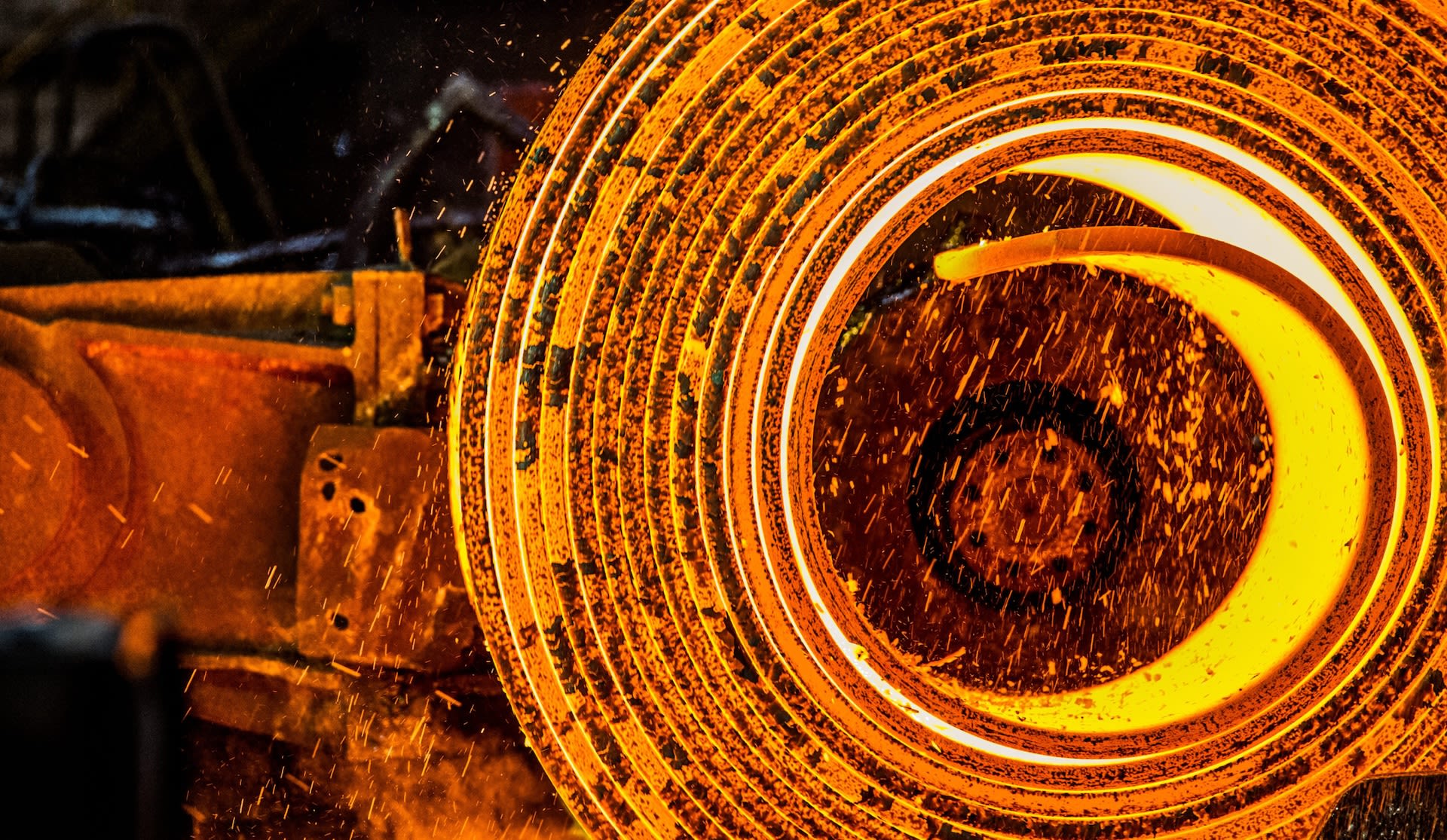

Steel touches every aspect of our lives and is the foundation of the modern economy.

Today, over six million people work in the steel industry worldwide, and it contributes around 3.8% to global GDP.

Yet, steel also contributes roughly 10% to global energy emissions, and there are numerous other issues associated with its production and supply chain. So what does responsible steelmaking look like?

With the support of our members and stakeholders, we've spent over a decade building the foundations for more responsible steelmaking, identifying key ESG issues in the industry, and rolling out the ResponsibleSteel International Production Standard globally.

In this first ResponsibleSteel Progress Report, we chart the steps made towards achieving our mission so far and look forward as we continue to build momentum and accelerate progress in the industry.

Message from

the Chair

We've spent the last decade building a strong foundation for ResponsibleSteel, predicated on high-quality standards, transparent processes, and the support of a thriving membership.

Over the past two years, the prospect of using standards to guide a net zero steel industry has started to occupy the minds of policymakers. ResponsibleSteel has been at the heart of this conversation, with our International Production Standard taking the lead in the push for a more sustainable industry.

Last year, in the IEA's report to the G7 on the subject of measurement standards, ResponsibleSteel was recognised as being “at the forefront among the shortlist of methodologies identified with respect to fitness for purpose for a net zero steel sector.”

I want to thank our members for their commitment and invaluable input into ResponsibleSteel's workstreams. This is what ensures that the organisation remains a global leader for steel sustainability and our international standards retain their reputation

for robustness and quality. And I want to encourage ResponsibleSteel members to continue to be visible in their support for ResponsibleSteel as we get ready for the next step in the journey - certified steel.

Gerry Tidd

Chairman, ResponsibleSteel

"ResponsibleSteel has enabled us to gain access to reliable, third-party verified and audited information that supports us in ensuring our steel is responsibly sourced. It also plays an integral role in ensuring that we safeguard human rights, biodiversity, water, and governance when procuring steel for our production cars. We aim for all our steel suppliers to be members of ResponsibleSteel and urge more steel companies to do the same."

Simon Buckingham

Volvo Cars

A Roadmap for Steel

The ResponsibleSteel International Production Standard consists of 13 Principles covering not only emissions but also labour rights, biodiversity, local communities and more, because responsible steelmaking must go beyond decarbonisation.

Certification against the Standard gives buyers, stakeholders and investors the confidence that certified sites are operating at some of the highest industry standards on all aspect of sustainability. To become certified, steelmaking sites must first undergo a rigorous audit carried out by independent qualified certification bodies. Sites that meet the Standard’s core requirements are awarded site certification.

The first steelmaking sites began achieving site certification against the Standard in July 2021. Today, we have certified sites across 14 countries.

And now to continue driving industry improvement, sites can take the next step and market their products as certified steel once they've met additional ‘Progress Levels’ for decarbonisation and responsible materials sourcing.

Note on reporting timeframes: The data from ResponsibleSteel's certification programme and membership has been calculated up to the end of February 2024.

Globally, we now have:

70

ResponsibleSteel

Certified Sites

Steel production sites: 22

Upstream sites: 4

Downstream sites: 38

And these sites collectively employ over:

225,000

workers

Direct workers: 48,182

Contract workers: 179,713

|

Female* |

Male* |

|---|---|

|

6,074 |

47,911 |

|

13% of workers |

87% of workers |

|

*data from 14/29 certificates |

|

124

million metric tons of steel

is produced by ResponsibleSteel certified sites every year.

Equivalent to

6.4%

of global steel production.

ResponsibleSteel certification covers:

16

Electric Arc Furnaces

In addition to:

42

Blast Furnace-Basic Oxygen Furnace

(BF-BOFs)

6.8%

(254.81 Mt CO2)

of the steel sector’s CO2e emissions come from ResponsibleSteel certified sites.

As part of their certification, these sites have committed to site-level targets in line with the Paris Agreement.

Their next step is to qualify to sell ResponsibleSteel certified steel.

“Three of Tata Steel’s production sites in Jamshedpur were certified by ResponsibleSteel in November 2022 - a first in India. This was followed by Meramandali and Kalinganagar plants in Odisha getting the certification in February this year. ResponsibleSteel certification not only validates our efforts but also enhances our credibility as a responsible global steel producer. Sustainability is at the core of everything we are doing at Tata Steel and working with institutions like ResponsibleSteel that help us to keep pushing the benchmarks is an important part of the exercise."

Rajiv Mangal

Vice President (Safety, Health & Sustainability), Tata Steel.

Building a Responsible Future for Steel

The journey

Image courtesy of BlueScope Port Kembla

Image courtesy of BlueScope Port Kembla

2013-2016

Inception

The Australian Steel Stewardship Forum develops the concept for an international, non-profit multi-stakeholder membership organisation to tackle the most pressing sustainability issues in the steel industry and ResponsibleSteel is incorporated as the Steel Stewardship Council.

October 2018

Forum I

The first ResponsibleSteel Forum is held in Berlin, Germany at the GIZ offices.

November 2019

Version 1.0

Following two years of development and input from over 70 stakeholders and 180 individuals from industry and civil society, the Standard – the first of its kind in the global steel industry – achieves multistakeholder consensus and is approved by a majority of business and civil society members.

December 2019

Forum II

Forum II is held in Wollongong, Australia.

December 2020

SteelZero launched

SteelZero is launched by ResponsibleSteel and The Climate Group. SteelZero aims to send a powerful signal to steel producers, investors and policymakers to accelerate the transition to widescale production of net-zero steel.

June 2021

Version 1.1

An updated version of the ResponsibleSteel Standard is published.

July 2021

First certified sites

ResponsibleSteel awards the world’s first certifications to four steelmaking sites in Belgium, Germany and Luxembourg owned by ArcelorMittal. The sites are the first steel plants to be audited against the ResponsibleSteel International Production Standard.

Image courtesy of ArcelorMittal Tubarão

Image courtesy of ArcelorMittal Tubarão

March - April 2022

First certified sites in North and South America

ArcelorMittal Tubarão in Brazil and Big River Steel, owned and managed by U. S. Steel in Arkansas, are awarded the first-ever ResponsibleSteel site certifications in the Americas.

September 2022

Version 2.0

The ResponsibleSteel Standard is updated to include additional requirements on responsible sourcing (Principle 3) and GHG emissions (Principle 10).

October - November 2022

Forum III

Forum III gathered nearly 200 delegates from over 70 organisations around the world in Memphis, USA, to hear from speakers from leading steel companies, downstream consumers, financial institutions, and civil society.

November 2022

5 continents and 100 million tonnes of steel

With the world’s largest steel sites achieving ResponsibleSteel certification (Pohang and Gwangyang Steelworks in South Korea operated by POSCO together with the Jamshedpur site in India operated by TATA Steel), there are certified sites on 5 continents covering the production of over 100 million tonnes of steel.

January 2023

ResponsibleSteel joins ISEAL as a Community Member

ResponsibleSteel is approved as an ISEAL Community Member, joining a growing group of members committed to supporting and improving sustainable practices.

September 2023

Near-Zero Steel 2030 Challenge

The World Economic Forum’s First Movers Coalition (FMC) together with RMI launches the Near-Zero Steel 2030 Challenge in collaboration with ResponsibleSteel, Greenhouse, Deloitte and BCG. The Challenge is created to map existing plans, accelerate emerging solutions, and connect potential suppliers of near-zero steel to companies ready to purchase it.

October 2023

Decarbonisation Progress Audit Tool launched

ResponsibleSteel launches a ‘Decarbonisation Progress Audit Tool’ to support steelmaking sites in preparing for external audits against Principle 10 of the ResponsibleSteel International Standard V2.0.

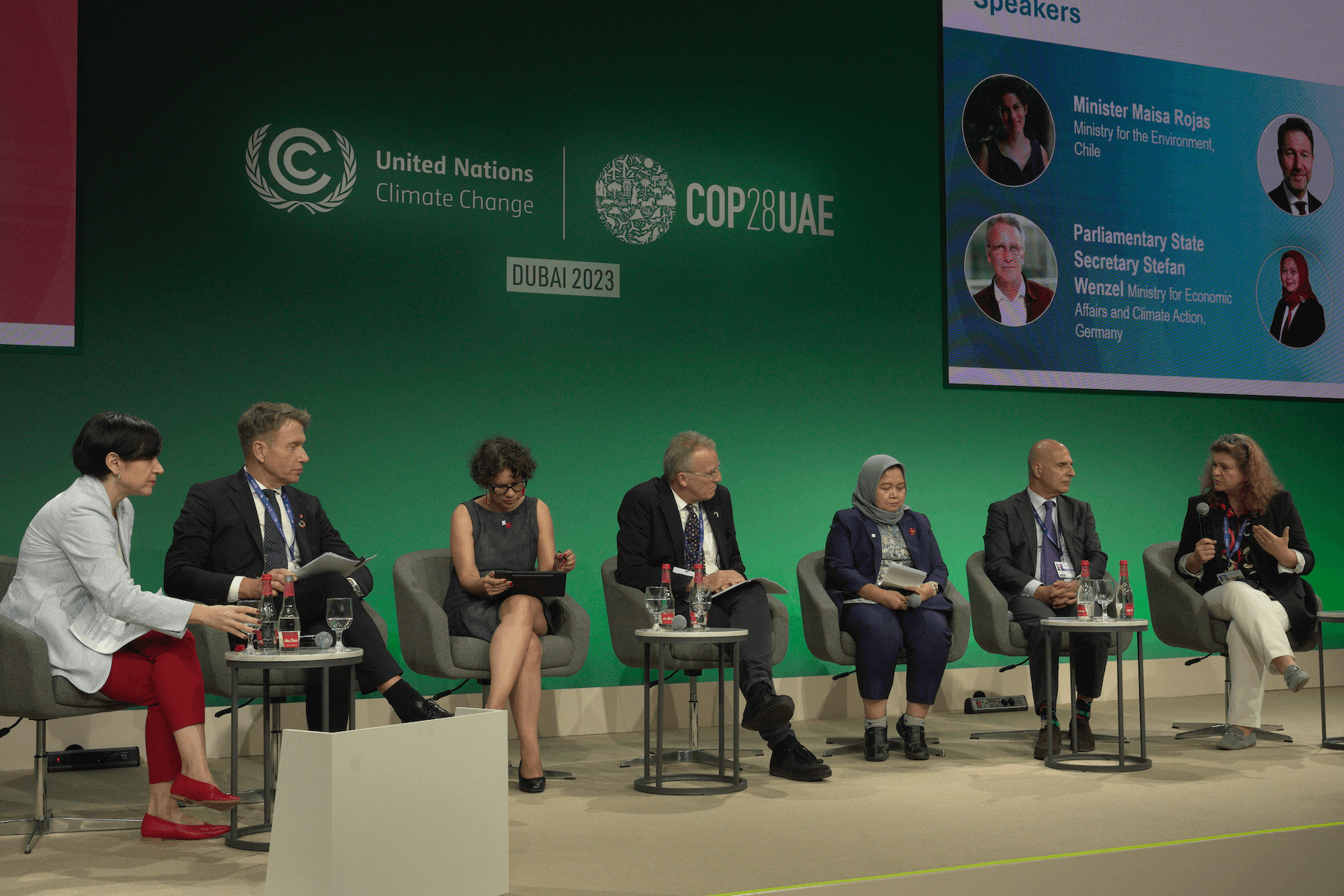

December 2023

Launch of the Steel Standards Principles at COP28

The Steel Standards Principles, a set of principles aimed at aligning how greenhouse gas emissions are measured in the steel sector, are launched by the World Trade Organization and ResponsibleSteel. The Principles call for establishing common methodologies for measuring greenhouse gas emissions within the iron and steel sector in order to accelerate the near-zero transition.

Image courtesy of Industeel

Image courtesy of Industeel

March 2024

Draft Chain of Custody Standard Published

ResponsibleSteel's new Chain of Custody Standard - the first of its kind in the steel industry - goes out for consultation. Along with the International Production Standard, this new standard will enable the flow of ResponsibleSteel certified steel into the market, and allow public claims to be made around sourcing.

A Global Alliance

Through a diverse multi-stakeholder membership, ResponsibleSteel has built a forum for businesses and social and environmental organisations to work together, creating value that neither group can create on its own.

We have brought together members from every step in the steel value chain as well as companies working in policy, education, technology, and beyond.

150 +

ResponsibleSteel Members

as of February 2024

Membership Growth, year on year

A multi-stakeholder organisation

ResponsibleSteel members are at the heart of our programme, ensuring that the standards, policies and tools that we develop remain robust, relevant, and credible.

Over 180 individuals contributed to the development of the first ResponsibleSteel Standard. This spirit of collaboration continues today with our members actively engaging in our working groups and the ongoing development of the ResponsibleSteel programme.

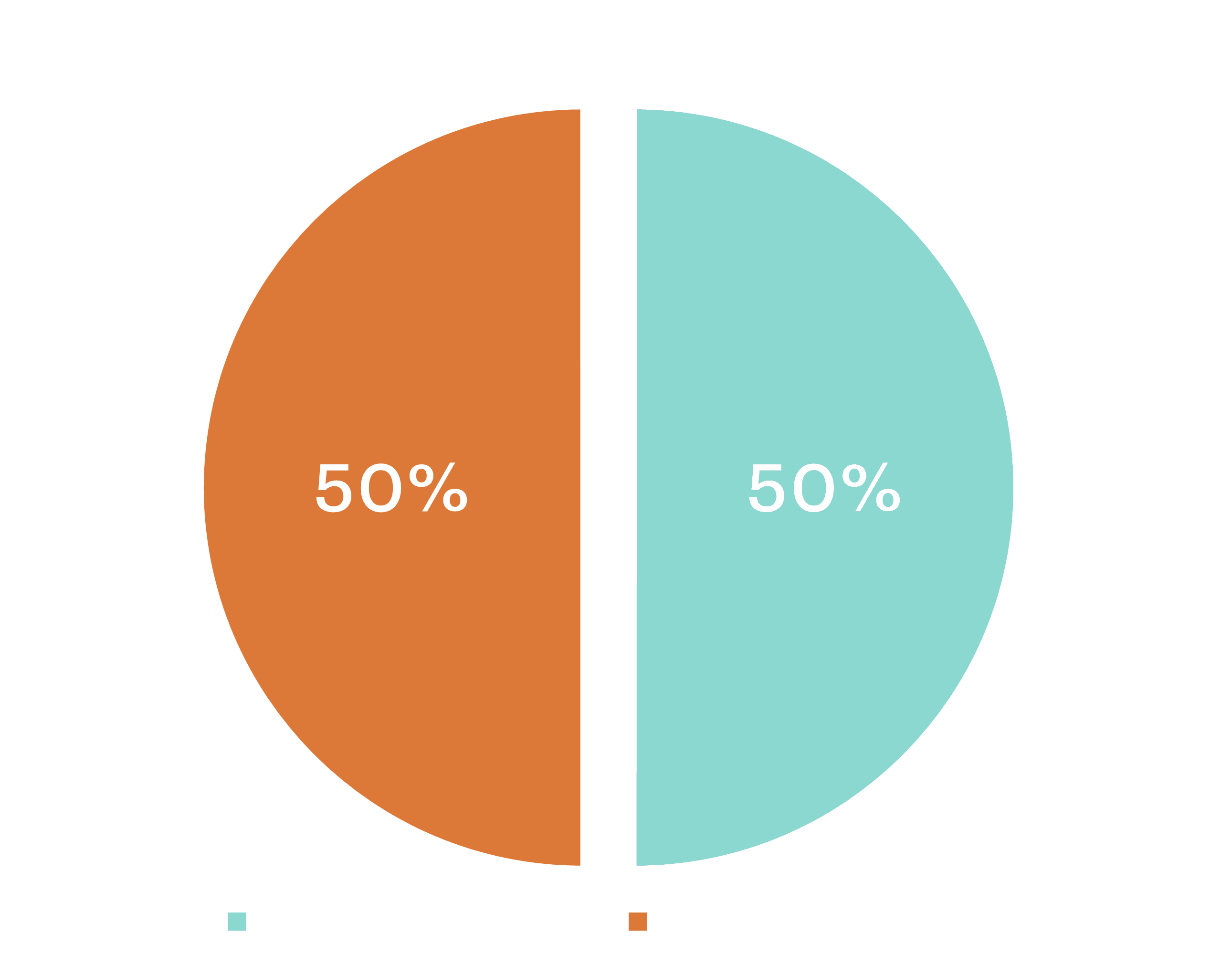

73 Business Members

15 Civil Society Members

63 Associate Members

Creating a robust and practical roadmap for steel requires input and buy-in from both business and civil society members. That's why ResponsibleSteel voting power is weighted 50% for each, irrespective of the number of members in the particular category.

Likewise, decisions on our standards and assurance programme, finances, policies, and procedures are made by our Board of Directors and must be supported by a two-thirds majority and by at least one civil society Director and one business Director.

We have members headquartered in

34 countries.

Asia

Europe

Middle East

North America

Oceania

South America

Certification in Action

Big River Steel

Sustainable thinking has been at the forefront of Big River Steel since ground was first broken on the site back in 2014. Big River Steel covers approximately 1,200 acres in Osceola, Arkansas bordered by the Mississippi River and has a 2.5 million tonne capacity. The site has gone from strength to strength since it opened its doors in 2016 and in 2021, it joined the U. S. Steel family as part of the wider ‘Best for All’ strategy.

Image courtesy of Big River Steel

Image courtesy of Big River Steel

U. S. Steel became the first North American steelmaking member in 2022.

“By joining ResponsibleSteel we are taking our efforts beyond goals and actually delivering profitable solutions for our stakeholders and the planet.”

When it came to selecting the first site to pursue ResponsibleSteel certification, the choice was instinctive. At the heart of Big River Steel are its people. Part of the appeal of seeking ResponsibleSteel certification was the fact that the International Production Standard does not focus solely on reducing emissions or mitigating environmental impacts, but also promotes a safe, healthy, and fair working environment.

Big River Steel employs over 890 workers and 300 contractors. Workers can be exposed to extreme temperatures (Big River Steel’s EAF furnaces can reach 3000 degrees Fahrenheit) and the hazards of operating extremely heavy machinery.

Back in 2021, in preparation for the ResponsibleSteel audit, Big River Steel implemented a Safety Committee Charter to ensure that workers had a say in the Operational Health and Safety (OHS) of the site. The Safety Committee now meets monthly and consists mostly of shift and daytime supervisors and production employees. Ahead of the initial audit, Big River Steel also began inviting members of the community and local leaders to partake annually in committee meetings. Committee members are given enhanced OHS training and serve as a voice for workers, the impact of which has already been felt across the site.

But the real challenge for Big River Steel came when minor non-conformities relating to the Standard’s requirements on labour were identified during the initial stage 2 audit conducted in February 2022.

The chief sticking point was around the Standard’s requirements relating to paid annual leave and maternity leave, prompting Big River Steel to implement new policies in January 2024. But according to Brown, Big River Steel is already seeing the benefits of certification as more and more customers demand sustainable steel. When it comes to competing with other steelmakers, certification has given Big River Steel an edge. According to Daniel Brown, Senior VP for Advanced Technology Steelmaking at U. S. Steel and Chief Operating Officer of Big River Steel, customers have already expressed to him, “We’ll choose you because you’re ResponsibleSteel certified.” Unsurprisingly, Big River Steel already has plans to undergo the process for steel certification in the near future.

Convening the Sector

Since its inception, ResponsibleSteel has invested in building alliances and partnerships across industry, policy and finance to accelerate progress on the journey to responsibly produced net-zero steel.

Image Courtesy of Gerdau S.A.

Image Courtesy of Gerdau S.A.

Steel Standards Principles

The Steel Standards Principles were launched with the WTO to establish key foundations for a common framework for climate-related steel standards. The Principles have already been endorsed by over 40 organisations calling for alignment on measuring steel emissions.

Image Courtesy of NLMK Russia

Image Courtesy of NLMK Russia

Near-Zero Steel 2030 Challenge

Led by the FMC in coalition with ResponsibleSteel, Greenhouse, RMI, Deloitte, and Boston Consulting Group, the Near-Zero Steel 2030 Challenge fills a critical gap in connecting potential near-zero steel buyers to steelmakers and steelmakers to the necessary funding and technology for production.

SteelZero

The first partner initiative launched by ResponsibleSteel with the Climate Group, SteelZero brings together buyers of steel committed to procuring net-zero steel, sending a powerful demand signal to global markets to accelerate the production of near- and net-zero steel.

“Decarbonizing the steel industry is critical to reaching our global climate goals, and the impact of the ResponsibleSteel International Standard toward these efforts across the supply chain cannot be overstated.”

Armond Cohen

Founder and President, Clean Air Task Force

On the Horizon

Keeping up Momentum

Now's the time to pick up the pace. ResponsibleSteel is broadening its reach and expanding it's programme, to ensure we move the entire industry toward responsible steel production.

Image Courtesy of NLMK Belgium

Image Courtesy of NLMK Belgium

ResponsibleSteel International Production Standard V2.1

Launching in May 2024, V2.1 will incorporate revisions to Principles 3 and 10 and provide the green light for steelmakers in the race to achieve the first ResponsibleSteel certified steel.

Image courtesy of Big River Steel

Image courtesy of Big River Steel

Certification Pathway to Net Zero by 2050

Following the launch of V2.1, we plan to publish in-depth analysis on the progress required to meet the goals of the Paris Agreement, through the lens of the ResponsibleSteel Decarbonisation Progress Levels.

Image Courtesy of NLMK Russia

Image Courtesy of NLMK Russia

Downstream Chain of Custody

ResponsibleSteel is currently piloting a new Downstream Chain of Custody Standard to be launched later in 2024, allowing downstream buyers of ResponsibleSteel certified steel to make claims for the first time.

Image courtesy of ArcelorMittal Tubarão

Image courtesy of ArcelorMittal Tubarão

High Alloy and Stainless Steels

We are currently developing technical specifications for the decarbonisation progress of sites producing High Alloy and Stainless Steels, to be open for public consultation soon.

Image Courtesy of POSCO South Korea

Image Courtesy of POSCO South Korea

Growing Recognition

ResponsibleSteel has already been recognised by the Australian and U.S. Green Building Councils and ranked as a leader in sustainability by Lead the Charge and Mercedes-Benz and we will continue to drive recognition of our Standard.

Image courtesy of ArcelorMittal Brasil

Image courtesy of ArcelorMittal Brasil

Review of the International Production Standard

In line with our International Standards Development Procedures, ResponsibleSteel will launch a full review of the International Production Standard later in 2024.

We've made huge strides on our journey toward more responsible steelmaking over the past decade - across all aspects of sustainability. I've watched as steel decarbonisation has come to the forefront of the climate agenda and issues such as gender equality have become a top priority for leading steel companies. It's heartening to see the profound appetite there is for driving real industry progress.

Now is the time to put our foot on the accelerator. It's clearer than ever that we need to move the entire global steel industry toward net zero at speed and scale to meet the goals of the Paris Agreement. And to do so responsibly. Amid a growing number of initiatives, ResponsibleSteel is playing a critical role in driving global alignment and reminding policymakers of the need for consistent transparency, a level playing field, and responsibilities that go far beyond decarbonisation.

I am always encouraged by our members' passion and commitment to driving ResponsibleSteel's mission. This is only the beginning. We have major developments coming this year, including a report charting steel's 1.5C certification pathway, our new Chain of Custody Standard, and the long-awaited launch of the world's first ResponsibleSteel certified steel, a springboard for the industry. Thank you for your continued support and I look forward to sharing these and other announcements with our stakeholders soon.

Annie Heaton

CEO, ResponsibleSteel

Come with us

Find out more about how you can support us

Additional information:

Image credits: BlueScope / ArcelorMittal / Big River Steel / Shutterstock / World Steel Association / Ternium / Pohang Steelworks (POSCO) / JSW / HBIS / Gerdau S.A. / NLMK / Tata Steel