SIJ Group achieved ResponsibleSteel Core Site Certification for its SIJ Acroni and SIJ Metal Ravne sites, and put Slovenia on the global map of sustainable steel production.

SIJ – Slovenian Steel Group (SIJ Group) is a leading producer of stainless steel and special steels in Europe.

The Group achieved ResponsibleSteel’s site certification in April 2024, meeting the Core requirements of the ResponsibleSteel International Production Standard.

The certification covers SIJ Acroni, producing rolled steel products, and SIJ Metal Ravne, producing forged and rolled products.

Pursuing ResponsibleSteel certification was an obvious choice for SIJ Group. The Group is a signatory of worldsteel’s Sustainable Development Charter and has long made efforts to be at the forefront of sustainable practice in the industry.

SIJ Group has aimed to operate in line with circular economy principles for almost four decades. Its first Electric Arc Furnace opened in the 1960s, and today around 78% of its steel input is scrap.

With the SIJ Acroni and SIJ Metal Ravne sites located amidst town suburbs, close to rivers and surrounding forestry, ongoing solutions were in place to mitigate the impact on the local community and environment.

“Working towards ResponsibleSteel certification provided a structured roadmap for our sustainability efforts.

It gives you a compass. We made the decision early on that relevant Principles of the ResponsibleSteel Standard would be applied across the whole Group, not just the sites that are certified.”

Tadeja Primožič Merkač

Director of Quality, Sustainability and Corporate Management, SIJ Group

The ResponsibleSteel certification makes SIJ Group an eligible borrower for the European Bank for Reconstruction and Development (EBRD), which facilitated and supported the certification process.

"The EBRD has always focused on applying environmental and social best practices, and ensuring all the projects it invests in comply with its Environmental and Social Policy.

Through achieving ResponsibleSteel site certification, SIJ Group has been able to implement sound ESG practices and ultimately assist in compliance with the EU CSRD/reporting and disclosures framework.

The certification also has commercial value as it helps to provide customers with information on sustainability issues associated with production."

Robert Adamczyk

Senior Environmental Advisor and Operations Head Energy Sector Team within the Environment and Sustainability Department, EBRD

A step-change in occupational health and safety

During the certification process, the greatest challenge SIJ Group faced related to the Production Standard’s Principle on Occupational Health and Safety.

Although SIJ’s health and safety procedures had improved over the past five years, the audit initially resulted in two major non-conformities.

The company instigated an overhaul of facilities, with site visits and corrective action, and the non-conformities were addressed and closed in a special audit.

The audit resulted in senior management, including the CEO, walking through the site to see what improvements were needed, visiting all areas, even toilet facilities.

This impressed upon employees the commitment of senior management to the certification process and to improving worker safety and wellbeing.

A screen in the SIJ Acroni plant displaying a message about the site's Core Site Certification. Image: ResponsibleSteel/Joe Woodruff

A screen in the SIJ Acroni plant displaying a message about the site's Core Site Certification. Image: ResponsibleSteel/Joe Woodruff

A worker at SIJ Acroni. Image: SIJ Group

A worker at SIJ Acroni. Image: SIJ Group

Personal protective equipment (PPE) at SIJ Acroni. Image: ResponsibleSteel/Joe Woodruff

Personal protective equipment (PPE) at SIJ Acroni. Image: ResponsibleSteel/Joe Woodruff

A control room at SIJ Acroni. Image: SIJ Group.

A control room at SIJ Acroni. Image: SIJ Group.

A worker at SIJ Acroni. Image: SIJ Group

A worker at SIJ Acroni. Image: SIJ Group

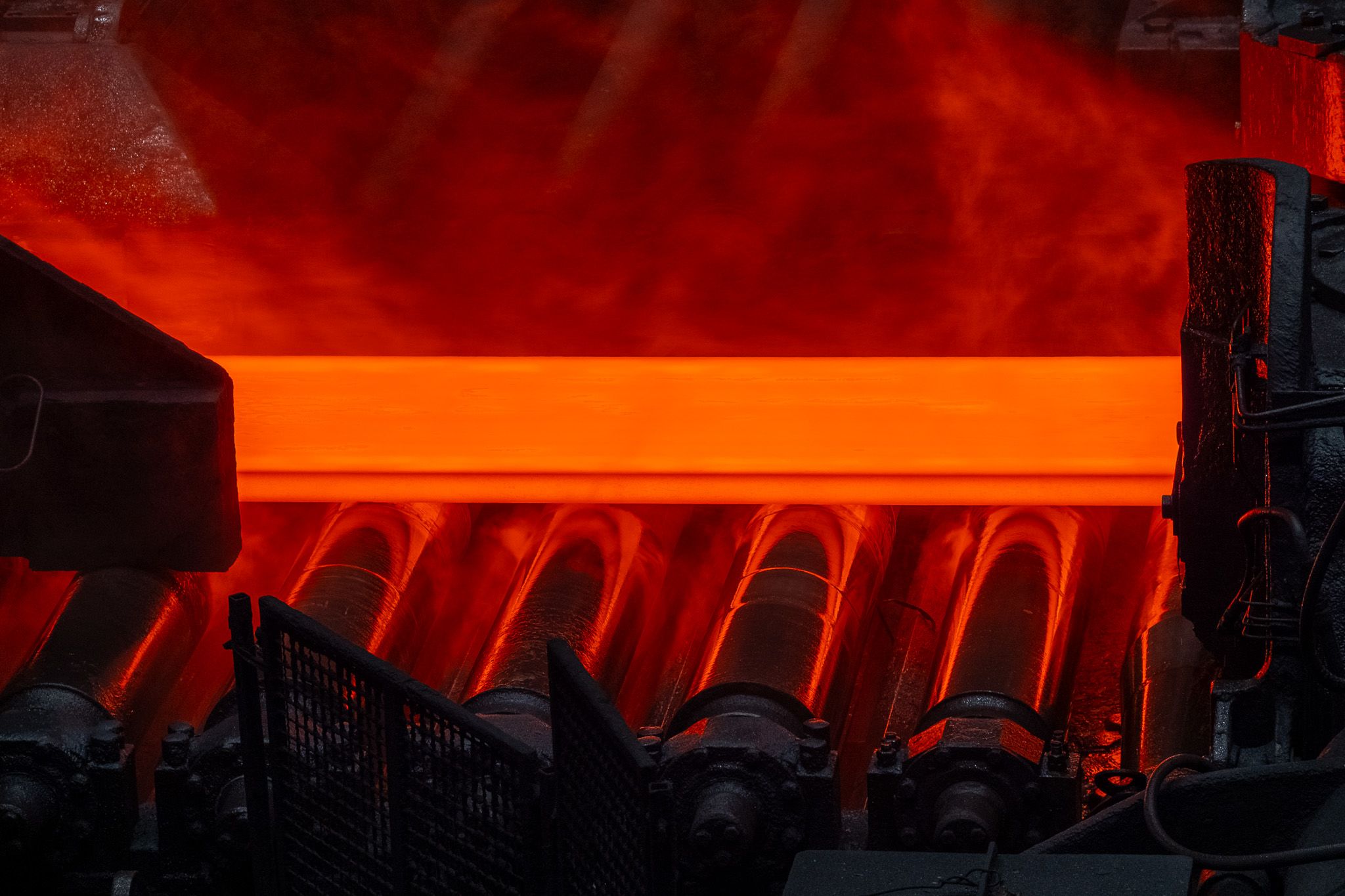

Hot rolling at SIJ Acroni. Image: ResponsibleSteel/Joe Woodruff

Hot rolling at SIJ Acroni. Image: ResponsibleSteel/Joe Woodruff

"From our point of view, a significant addition was a laser system that projected lines onto the floor, indicating the limit for approaching heavy loads.

This was particularly useful because, when carrying heavy loads, people might unconsciously step too close, creating a dangerous situation. Seeing the laser on the ground served as a clear safety measure."

Damir Musić

Levelling Operator, SIJ Acroni

Supporting environmental goals through the certification process

A ladle at SIJ Acroni. Image: ResponsibleSteel/Joe Woodruff

A ladle at SIJ Acroni. Image: ResponsibleSteel/Joe Woodruff

Scrap metal at SIJ Acroni. Image: ResponsibleSteel/Joe Woodruff

Scrap metal at SIJ Acroni. Image: ResponsibleSteel/Joe Woodruff

Preparing to meet the criteria for the Production Standard’s Principles on Climate Change and Greenhouse Gas Emissions, and Noise, Emissions, Effluents, and Waste, helped SIJ Group synthesise and build on its environmental achievements.

The Production Standard requires companies to demonstrate their commitment to the goals of the Paris Agreement through the development of science-based emissions reduction targets.

Company targets must be translated into a plan at the site level, and emissions monitored to determine whether these targets are being met.

SIJ Group developed its sustainability strategy in 2022, setting ambitious targets. The group aims to reduce carbon emissions (scope 1) by 51% by 2030 compared to the 2020 baseline and become carbon neutral by 2050.

The Group was already certified for Quality (ISO 9001), Environment (ISO 14001), and Energy Management (ISO 50001), which was another contribution to the successful ResponsibleSteel certification.

SIJ Group uses scrap supplied through its scrap collecting business and internal steel scrap. All steel recycled materials, sorted by chemical properties or quality, are reintroduced into the production process, thus reducing the share of pure alloys.

The Group’s emissions reduction strategy includes upgrading furnaces and burner technologies, replacing gas with electricity, reusing waste heat, optimising production with advanced tools, and replacing gas with hydrogen and biomass.

All water loops are closed with water brought back into use with cooling and filtration systems.

The certification process involved dedication and expertise from a range of employees across the Group. Great commitment to becoming certified was demonstrated when Slovenia’s Koroška region was hit by severe flooding, impacting SIJ’s Metal Ravne operations in the weeks prior to the audit.

Additionally, when considering ResponsibleSteel’s Principle on Biodiversity, the team was required to conduct a biodiversity study but initially struggled to find a company to undertake this.

The study was useful as it confirmed the Group’s assumptions that SIJ Acroni and SIJ Metal Ravne had no significant impact on local biodiversity.

Hills around the SIJ Acroni plant in northern Slovenia. Image: SIJ Group

Hills around the SIJ Acroni plant in northern Slovenia. Image: SIJ Group

Increasing employee satisfaction

A worker at SIJ Acroni. Image: ResponsibleSteel/Joe Woodruff

A worker at SIJ Acroni. Image: ResponsibleSteel/Joe Woodruff

One of the most significant steps forward during the certification process was improved employee communication, with implementation of the Production Standard receiving the attention of senior management and the Group’s majority shareholder.

According to Damir Musić, many workers at SIJ Acroni recognised the changes that came with ResponsibleSteel certification.

Following improvements to worker facilities and cleanliness, notably in restrooms, eating halls, and showers, there is now a programme to manage cleanliness and upkeep.

Workers feel they were heard and are proud of their workplace.

Image: ResponsibleSteel/Joe Woodruff

Image: ResponsibleSteel/Joe Woodruff

“Initially, some workers may have expected something different, but in the end, they saw the benefits.

The process kept employees engaged and provided them with new challenges and opportunities for improvement.

It wasn’t just about following rules—it was about creating a safer, more efficient work environment."

Damir Musić,

Levelling Operator, SIJ Acroni

Collaborating with community groups leads to strong community engagement

The certification requirements strengthened SIJ Group’s already strong community relations.

The Group has supported various community projects, such as the creation of 24 steel street workout areas designed and made by SIJ employees and, in cooperation with different municipalities, built three sustainable pump track playgrounds made of recycled slag aggregate.

ResponsibleSteel certification has signalled to the local population that the company is actively working to reduce its environmental impact and improve quality of life for the community.

A pump track, funded by SIJ Group, in a nearby community. Image: ResponsibleSteel/Joe Woodruff

A pump track, funded by SIJ Group, in a nearby community. Image: ResponsibleSteel/Joe Woodruff

Matej Brus, President of local community Koroška Bela. Image: ResponsibleSteel/Joe Woodruff

Matej Brus, President of local community Koroška Bela. Image: ResponsibleSteel/Joe Woodruff

“It was a slow start, but I believe we have significantly improved communication on both sides. I genuinely feel that the door is always open for us.

We can always reach out to company representatives with any questions or concerns that people in this area might have, and we receive almost immediate responses.

This has resulted in improved trust, which is essential because there is always an inherent trust issue when a local community, often the weaker participant, interacts with a large corporation.”

Matej Brus

President of local community Koroška Bela, the closest community to SIJ Acroni.

The sustainability journey continues

SIJ recognises that the path to sustainability is a continuous process of learning and improvement. The Group is committed to maintaining the certification of the SIJ Acroni and SIJ Metal Ravne sites by participating in surveillance and re-certification audits.

SIJ Group is also contributing to ResponsibleSteel’s High Alloy and Stainless-Steel Emissions Threshold Development Project, which aims to enable high alloy and stainless steelmakers to market and sell their products as ResponsibleSteel Certified Steel.

The changes made during the ResponsibleSteel certification process helped SIJ Group score high above the industry’s average in the S&P Global Corporate Sustainability Assessment.

The Group is also pursuing CDP reporting and SBTi membership, as well as meeting EU Sustainability Reporting Standards (ESRS) requirements to conduct sustainability audits alongside financial audits.

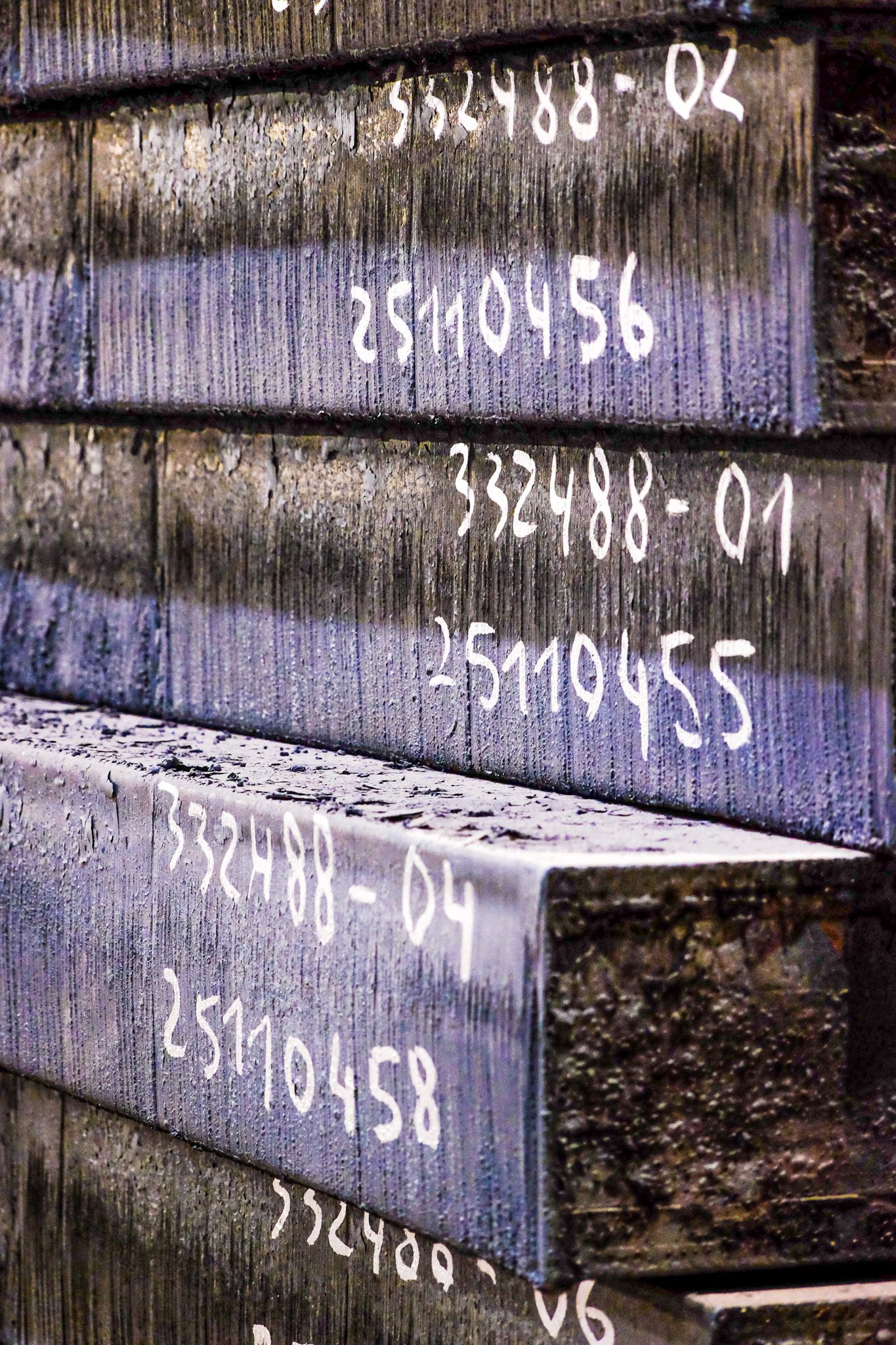

Steel slabs at SIJ Acroni. Image: ResponsibleSteel/Joe Woodruff

Steel slabs at SIJ Acroni. Image: ResponsibleSteel/Joe Woodruff

Andrey Zubitskiy, President of the Management Board of the SIJ Group. Image: SIJ Group

Andrey Zubitskiy, President of the Management Board of the SIJ Group. Image: SIJ Group

“Obtaining ResponsibleSteel certification represents a new sustainability milestone in the history of SIJ Group.

We are now part of a select group of steelmaking companies worldwide that are setting standards for sustainable practices in our industry.

It reflects our commitment to our employees, the community, and the environment in which we operate.”

Andrey Zubitskiy

President of the Management Board of the SIJ Group.

Come with us

Want to download this case study?

Find out more about how you can support us: