Progress

Report

2025

Progress

Report

2025

ResponsibleSteel is fast becoming the reference tool to drive the demand, policy, and finance levers necessary for transition.

ResponsibleSteel's standards, certification, and assurance programmes provide the steel industry with a sustainability roadmap to measure and reward progress that customers, communities, investors, and workers can all get behind.

We are committed to measuring and reporting on the progress of ResponsibleSteel’s programmes - on the achievements of steelmakers demonstrating leadership through ResponsibleSteel certification and on the expansion of our membership working to amplify and accelerate our mission.

ResponsibleSteel’s annual Progress Report provides an opportunity not only to celebrate these developments but also to identify areas for learning and improvement.

In this second ResponsibleSteel Progress Report, we mark the milestones achieved and new work undertaken in 2024, track the growth of ResponsibleSteel's membership, and evaluate the progress of our certification programme as we look toward 2030 and beyond.

Note on reporting timeframes: The data from ResponsibleSteel's certification programme and membership has been calculated up to the end of December 2024. While the first Progress Report calculated data up to the end of February 2024, we have chosen to draw comparisons to data from December 2023 to demonstrate year-on-year growth.

Message from the Chair

The steel industry faces significant challenges – market volatility, rising energy costs, global competition, and supply chain disruptions. In times of uncertainty, leaders stick to their long-term course. For the steel industry, this means charting sustainability progress that is credibly and consistently assessed.

ResponsibleSteel certification remains the most trusted path, not just to ‘low emissions steel’ but to ‘responsible low emissions steel’. The numbers speak for themselves. Core Site Certifications rose by 34% in 2024, and the first re-certifications were completed.

2024 also saw the launch of the first Certified Steel on the market, a milestone widely welcomed by both industry and civil society.

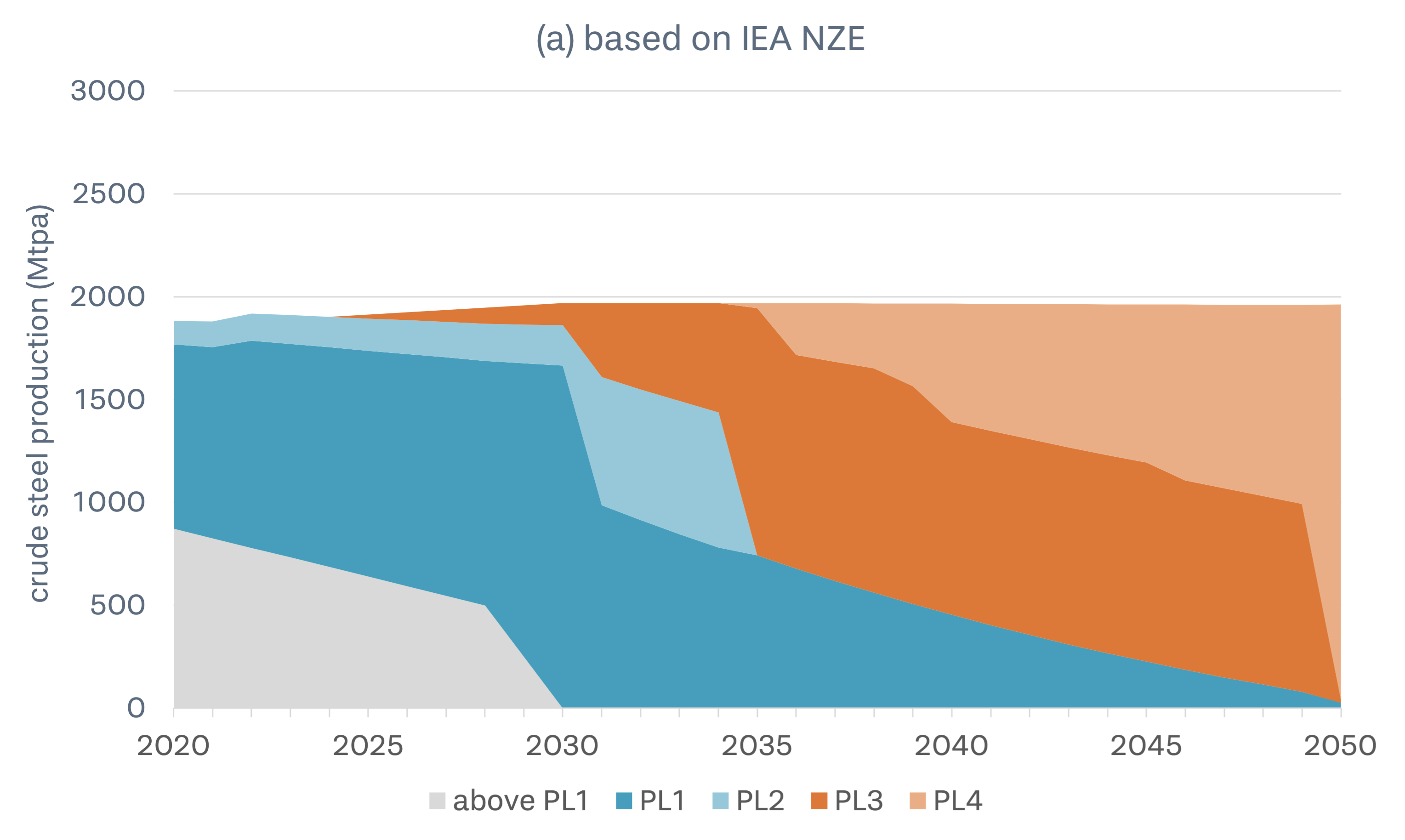

Our members, including Climate Group and SteelWatch, are using Certified Steel as an indicator of the industry’s progress. The industry is positioned to build on this momentum. At least half of the global industry is currently able to meet the first Decarbonisation Progress Level 1 for Certified Steel, and many sites can meet Level 2. Now, a growing number of iron ore mines have been successfully assessed against IRMA75, facilitating steelmakers to achieve up to Progress Level 4 for Materials Sourcing.

ResponsibleSteel’s approach to classifying effective progress to near zero, using the scrap-variable scale, is becoming the de facto technique, supported by the International Energy Agency, the First Movers Coalition and the Climate Group’s SteelZero.

2024 saw the launch of similar frameworks from LESS and the Chinese Iron and Steel Association, both echoing this approach.

ResponsibleSteel provides the pathway to responsible, near-zero steel production, but our success relies on continued commitment and ambition from our members and partners.

Steelmakers, buyers, material suppliers, policymakers, and investors all have crucial roles to play.

I want to thank our members and partners for their unwavering support. It is your dedication to our mission that ensures ResponsibleSteel remains an effective platform to drive progress.

Gerry Tidd

Chairman, ResponsibleSteel

Message from the Chair

Gerry Tidd

Chairman, ResponsibleSteel

The steel industry faces significant challenges – market volatility, rising energy costs, global competition, and supply chain disruptions. In times of uncertainty, leaders stick to their long-term course. For the steel industry, this means charting sustainability progress that is credibly and consistently assessed.

ResponsibleSteel certification remains the most trusted path, not just to ‘low emissions steel’ but to ‘responsible low emissions steel’. The numbers speak for themselves. Core Site Certifications rose by 34% in 2024, and the first re-certifications were completed.

2024 also saw the launch of the first Certified Steel on the market, a milestone widely welcomed by both industry and civil society.

Our members including Climate Group and SteelWatch are using Certified Steel as an indicator of the industry’s progress. The industry is positioned to build on this momentum. At least half of the global industry is currently able to meet the first Decarbonisation Progress Level 1 for Certified Steel, and many sites can meet Level 2. Now, a growing number of iron ore mines have been successfully assessed against IRMA75, facilitating steelmakers to achieve up to Progress Level 4 for Materials Sourcing.

ResponsibleSteel’s approach to classifying effective progress to near zero, using the scrap-variable scale, is becoming the de facto technique, supported by the International Energy Agency, the First Movers Coalition and the Climate Group’s SteelZero.

2024 saw the launch of similar frameworks from LESS and the Chinese Iron and Steel Association, both echoing this approach.

ResponsibleSteel provides the pathway to responsible, near-zero steel production, but our success relies on continued commitment and ambition from our members and partners.

Steelmakers, buyers, material suppliers, policymakers, and investors all have crucial roles to play.

I want to thank our members and partners for their unwavering support. It is your dedication to our mission that ensures ResponsibleSteel remains an effective platform to drive progress.

2024:

Key Moments

March

Launch of draft Chain of Custody Standard

The first draft of a Chain of Custody Standard was launched in March for a 60-day public consultation to gather member and stakeholder feedback. The draft standard was developed to enable downstream buyers sourcing Certified Steel to make credible claims relating to the use of Certified Steel in their products.

May

Publication of first-ever Progress Report

In the first annual ResponsibleSteel Progress Report, we charted our major milestones and achievements from our earliest days as an organisation.

Launch of the Production Standard Version 2.1

Version 2.1 incorporated key revisions to Principles 3 and 10 of the Production Standard relating to responsible materials sourcing and decarbonisation. It marked the green light for steelmaking sites intending to pursue Certified Steel.

July

New report published: Charting progress to 1.5°C through certification

Using two base scenarios – the International Energy Agency’s (IEA) Net Zero Emissions by 2050, and the Mission Possible Partnership’s (MPP) Carbon Cost – this report demonstrated to investors, buyers, and policymakers, the value of ResponsibleSteel's Decarbonisation Progress Levels to map the progress needed for the global steel industry to achieve the climate commitments under the Paris Agreement.

The Modern Steel Act introduced to the US Congress

The Modern Steel Act cited the ResponsibleSteel International Production Standard V2.1 as the reference standard for the measurement of mine-to-metal steel emissions and the classification of near-zero steel.

September

Announcement of the first Certified Steel

At Climate Week NYC, we announced the achievement of the first Certified Steel by U. S. Steel's Big River Steel site. For the first time, ResponsibleSteel Certified Steel hit the market with 2.4 million tonnes available.

October

Standard review and revision begins

We launched the review process of the ResponsibleSteel International Production Standard, beginning with a public consultation on proposed areas for revision. The Production Standard is reviewed every five years to assess whether and where there is a need for revision. This is what ensures that the Production Standard remains effective and relevant to the industry.

“Congratulations to U. S. Steel’s Big River Steel and ResponsibleSteel on the announcement of the first Certified Steel. From an end-user perspective, this is a really important step forward for both steelmakers and ResponsibleSteel – it’s truly a landmark moment. Looking ahead, who's going to be next?"

Simon Buckingham

Technical Leader - Sustainable Materials, Volvo Cars

Insights from our Certification Programme

In 2024:

22

new sites achieved Core Site Certification.

This marks a 34% increase in the number of certified sites from 2023.

In 2024, the first sites in Vietnam, Canada, Italy, Slovenia, Finland, and Sweden were certified, and the first re-certifications were also conducted, with 16 sites completing re-certification.

We launched the

First

Certified Steel.

At Climate Week NYC 2024, we announced the first Certified Steel alongside U. S. Steel, achieved by their Big River Steel site in Osceola, Arkansas.

Measured against the global benchmarking system provided by ResponsibleSteel’s International Production Standard, Big River Steel achieved Decarbonisation Progress Level 1 and Materials Sourcing Progress Level 1.

Big River Steel's Decarbonisation Progress Level was based on a 57.3% scrap content and 1.34t CO2e per tonne of crude steel.

Big River Steel produces

2.4

million tonnes of Certified Steel

Certified Sites as of December 31, 2024. Please note, this map includes two POSCO certifications in South Korea which expired in January 2025.

Globally, we have:

87

ResponsibleSteel

Certified Sites

Growth of certified sites year-on-year:

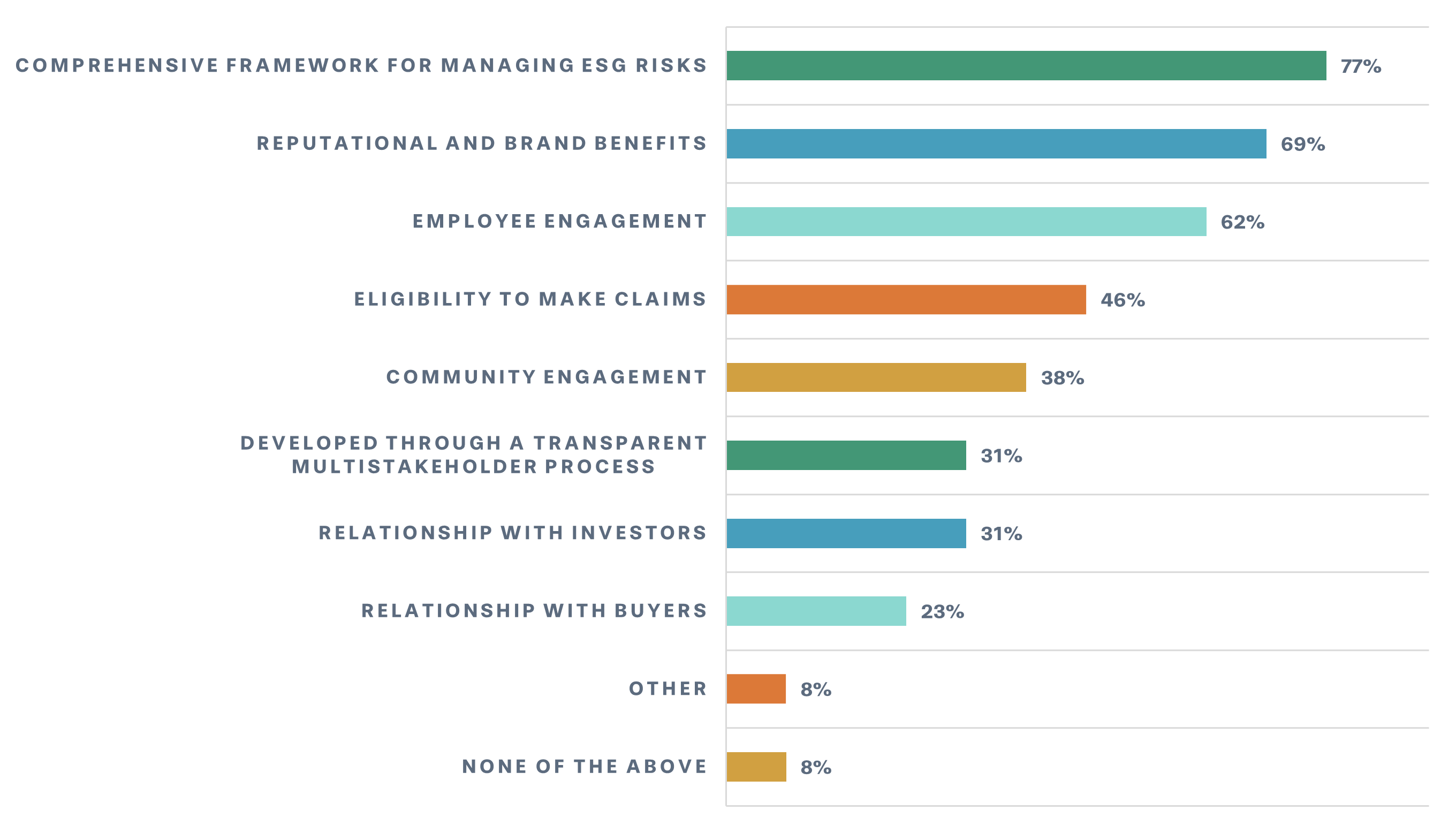

What value do sites see from certification?

Certificate holders see the value of ResponsibleSteel certification above all for its ability to support risk management, strengthen brand reputation, and engage employees.

Based on data from ResponsibleSteel's 2024 Membership Survey

Certified sites collectively employ over:

236,000

workers

A 27% increase from over 185,000 workers in December 2023.

Direct workers: 108,413

Contract workers: 127,760

|

|

|

Female |

Male |

|

10% of workers* |

90% of workers* |

*Direct workers only based on information from 25 certificates.

Note: This reflects a change from the previous Progress Report (13% female / 87% male), which was based on data from 14 of 29 certificates. The latest data covers 25 of 36 certificates. As our certification programme matures, we’re working to improve data availability.

Certified sites produce:

140

million metric tons of steel yearly.

A 21% increase compared to 116 million metric tons produced by ResponsibleSteel certified sites in 2023.

Equivalent to:

7.4%

of global steel production.

Compared to 6.1% of global production in 2023, based on 2023 and 2024 data from the World Steel Association.

“The ResponsibleSteel Standard provides a systematic framework to evaluate the sustainability of steel holistically. While the steel industry accounts for 10% of global GHG emissions, it plays a pivotal role in the green transition. We were proud to receive the certificate in 2024 as the first mover in the Nordics.”

Anna Vainikainen

Head of Human Rights, Outokumpu

Certification covers:

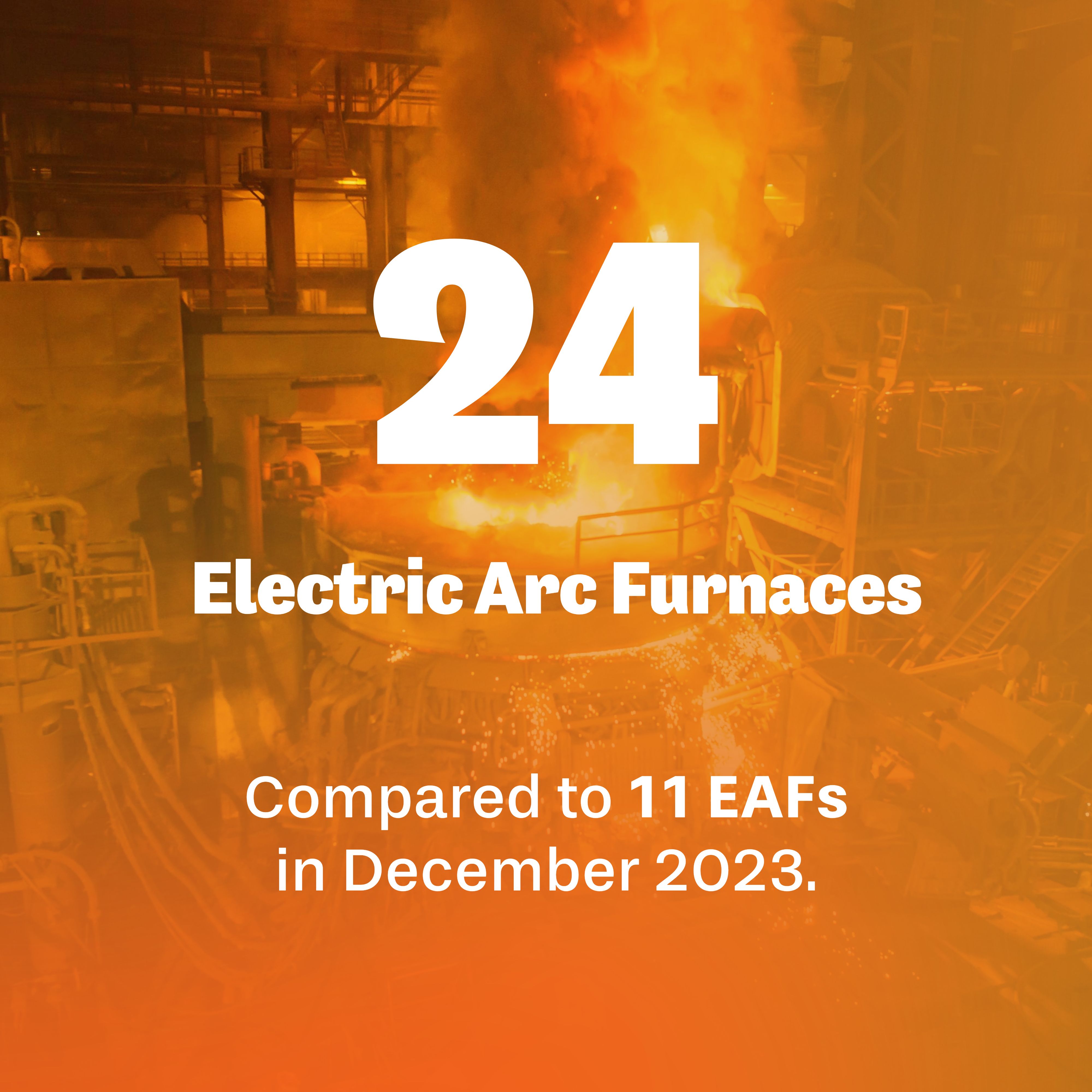

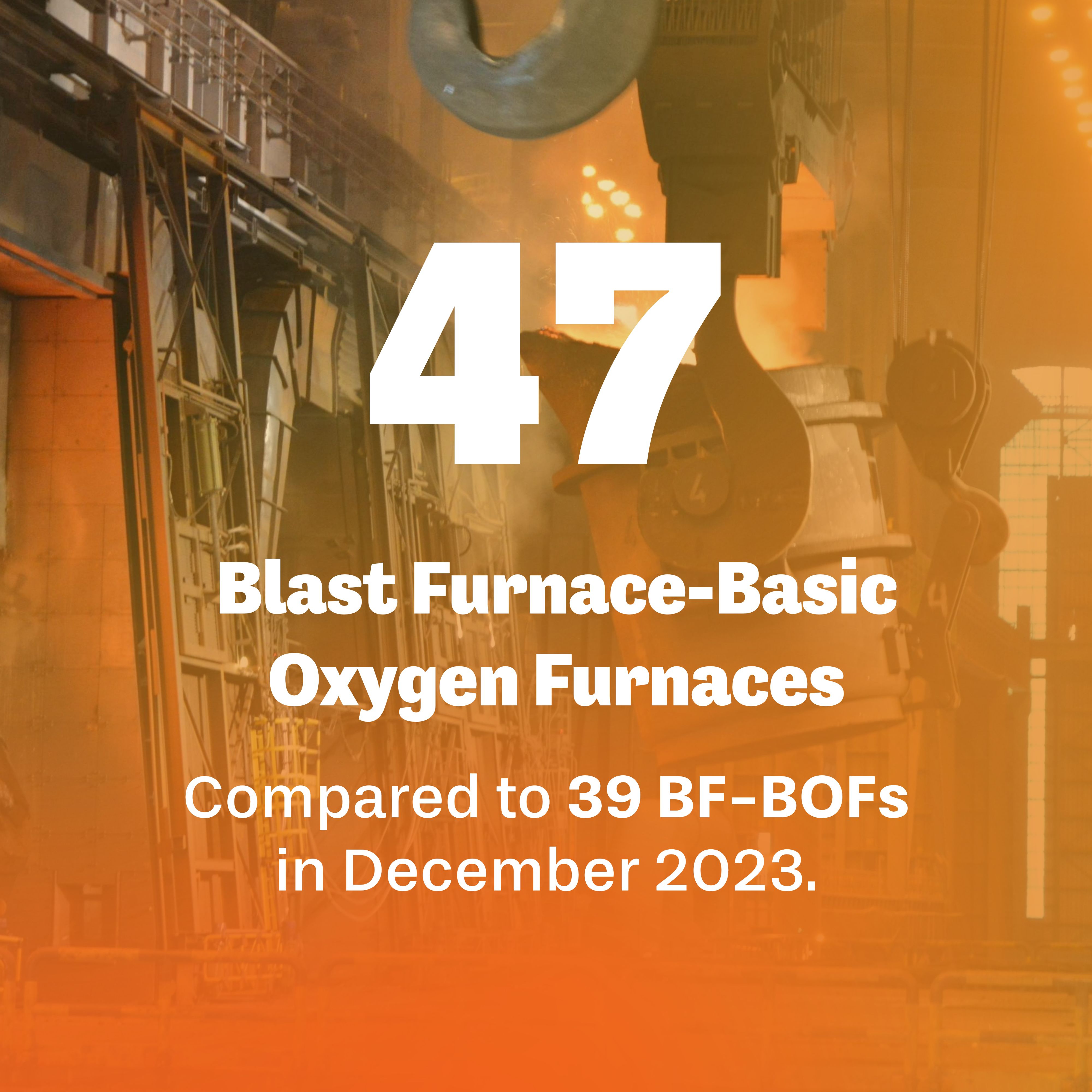

The ratio of EAFs to BF-BOF sites increased from

1 in 3 in 2023 to 1 in 2 in 2024.

273 mt CO2e

Equivalent to 7.6% of the steel sector’s CO2e emissions come from ResponsibleSteel certified sites.

This is significant - as part of their certification, all of these sites have committed to site-level targets in line with the Paris Agreement.

Now it's time for steel sites to take the next steps:

1. Assess your embodied CO2e emissions using ResponsibleSteel's methodology

2. Trace your suppliers to understand where your materials come from

3. Get audited for Certified Steel

Developments to our standards programme

ResponsibleSteel is committed to continuously improving our standards and certification programmes to ensure these remain aligned with industry needs. These developments are a collaborative effort, involving consultations with our members and wider industry stakeholders.

Revision of the Production Standard

Following a review and a public consultation in 2024, the ResponsibleSteel Board of Directors approved the decision to revise the ResponsibleSteel International Production Standard.

ResponsibleSteel is currently in the process of revising and updating the programme for the revision of the Production Standard, which will be available later this year. The programme will include details of stakeholder consultation opportunities.

We value your input - please look out for more information about this in the newsletter later in 2025.

Development of Chain of Custody Standard

Developing a Chain of Custody Standard is crucial to building demand for ResponsibleSteel Certified Steel and ensuring credible, verifiable claims.

In 2024, we launched a draft Chain of Custody Standard and opened it to public consultation. After integrating feedback from that consultation, in 2025, we will be pilot testing the draft standard. Once the results of the pilot test have been reviewed and considered, the draft will be revised and made available for a second public consultation. We encourage all members and stakeholders with an interest in this to keep an eye out and get involved in the consultation.

Development of Progress Levels for HASS

We began work on a High Alloy and Stainless Steel (HASS) project last year to develop lower/near-zero emissions thresholds for steels with over 8% alloy content. The project aims to develop a globally applicable HASS thresholds system that will allow high alloy and stainless steelmakers to market and sell their products as ResponsibleSteel Certified Steel.

We convened a working group and are now collecting global data to develop these thresholds, which will be open for public consultation in 2025. Our membership will have the opportunity to vote on these thresholds once finalised.

A global network

“Our ResponsibleSteel membership strengthens collaboration between the two standards beyond the Steel Standards Principles reinforcing a commitment to sustainability and climate responsibility in steel production."

Dr. Martin Theuringer

Chief Economist and Managing Director, German Steel Association and Secretary General, Low Emission Steel Standard (LESS)

ResponsibleSteel has built a global network of businesses and social and environmental organisations to accelerate the responsible production of steel through collaboration and mutual commitment.

In 2024, we welcomed:

20

new members

A 13% increase in 2024, further contributing to the continuous growth ResponsibleSteel has experienced since 2019.

At the end of 2024, we had:

169

ResponsibleSteel members

ResponsibleSteel has built a global network of businesses and social and environmental organisations to accelerate the responsible production of steel through collaboration and mutual commitment.

In 2024, we welcomed:

20

new members

A 13% increase in 2024, further contributing to the continuous growth ResponsibleSteel has experienced since 2019.

At the end of 2024, we had:

169

ResponsibleSteel members

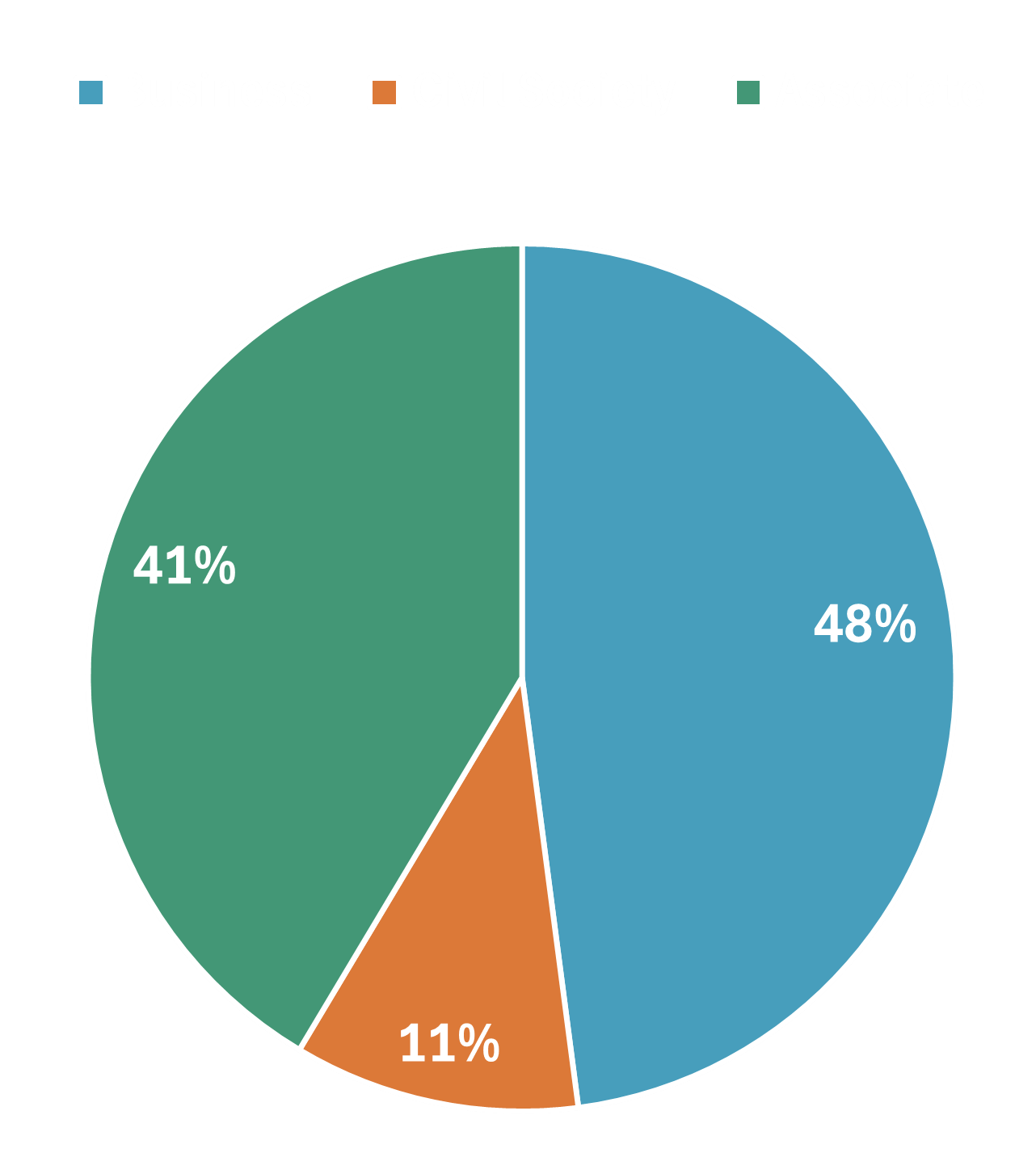

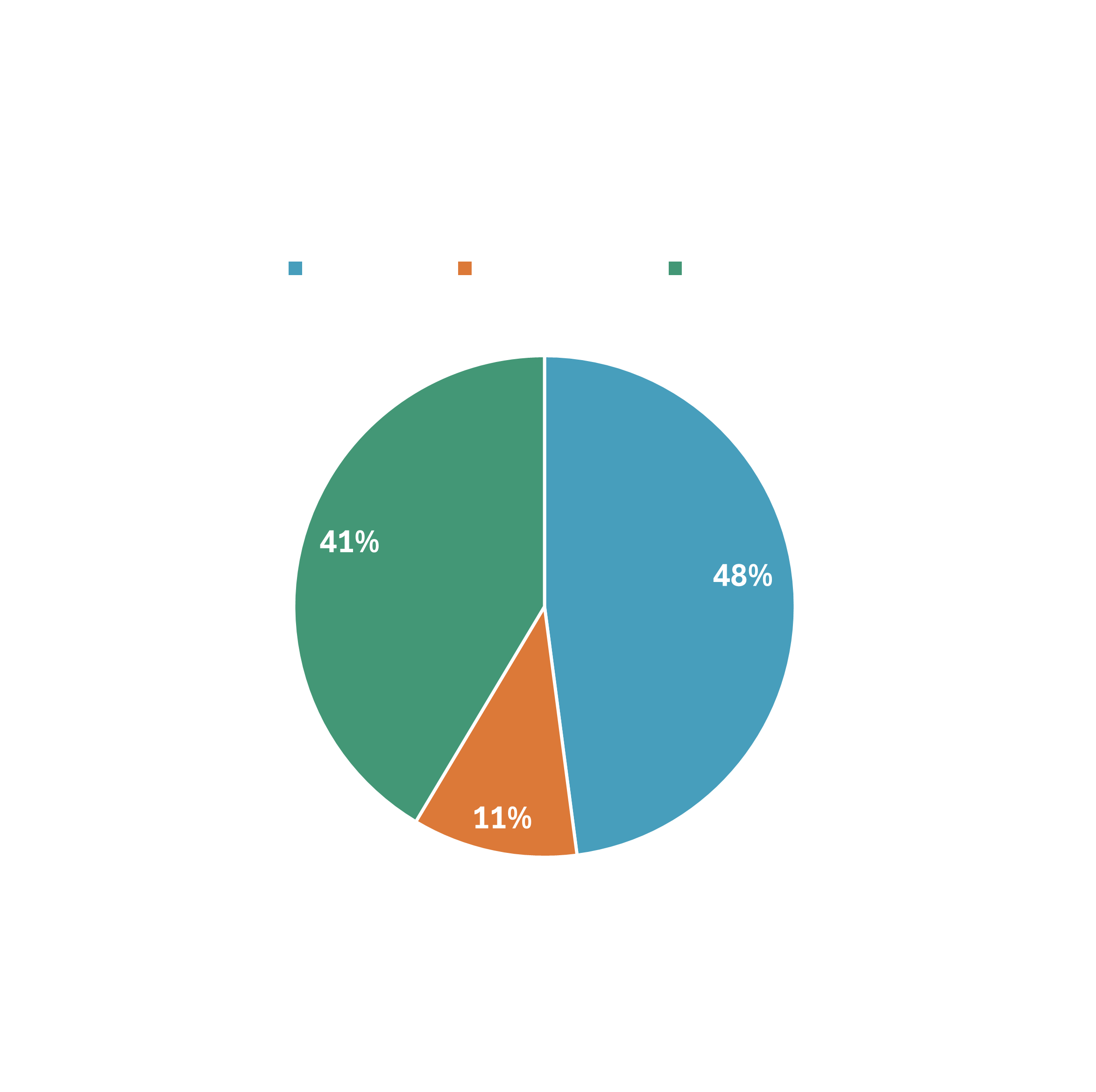

A multi-stakeholder organisation

ResponsibleSteel members span the entire steel supply chain from mining companies and input materials suppliers to end users, as well as civil society organisations, all working together to drive our collective mission.

81 Business Members

18 Civil Society Members

70 Associate Members

A multi-stakeholder organisation

ResponsibleSteel members span the entire steel supply chain from mining companies and input materials suppliers to end users, as well as civil society organisations, all working together to drive our collective mission.

81 Business Members

18 Civil Society Members

70 Associate Members

“We have worked with ResponsibleSteel since its founding, as we are both systems ultimately accountable to multi-stakeholder boards. We have always appreciated their emphasis on the role of steel producers to clearly value responsible practices at the mine site and bring transparency to the full supply chain.”

Aimee Boulanger

Executive Director, Initiative for Responsible Mining Assurance (IRMA)

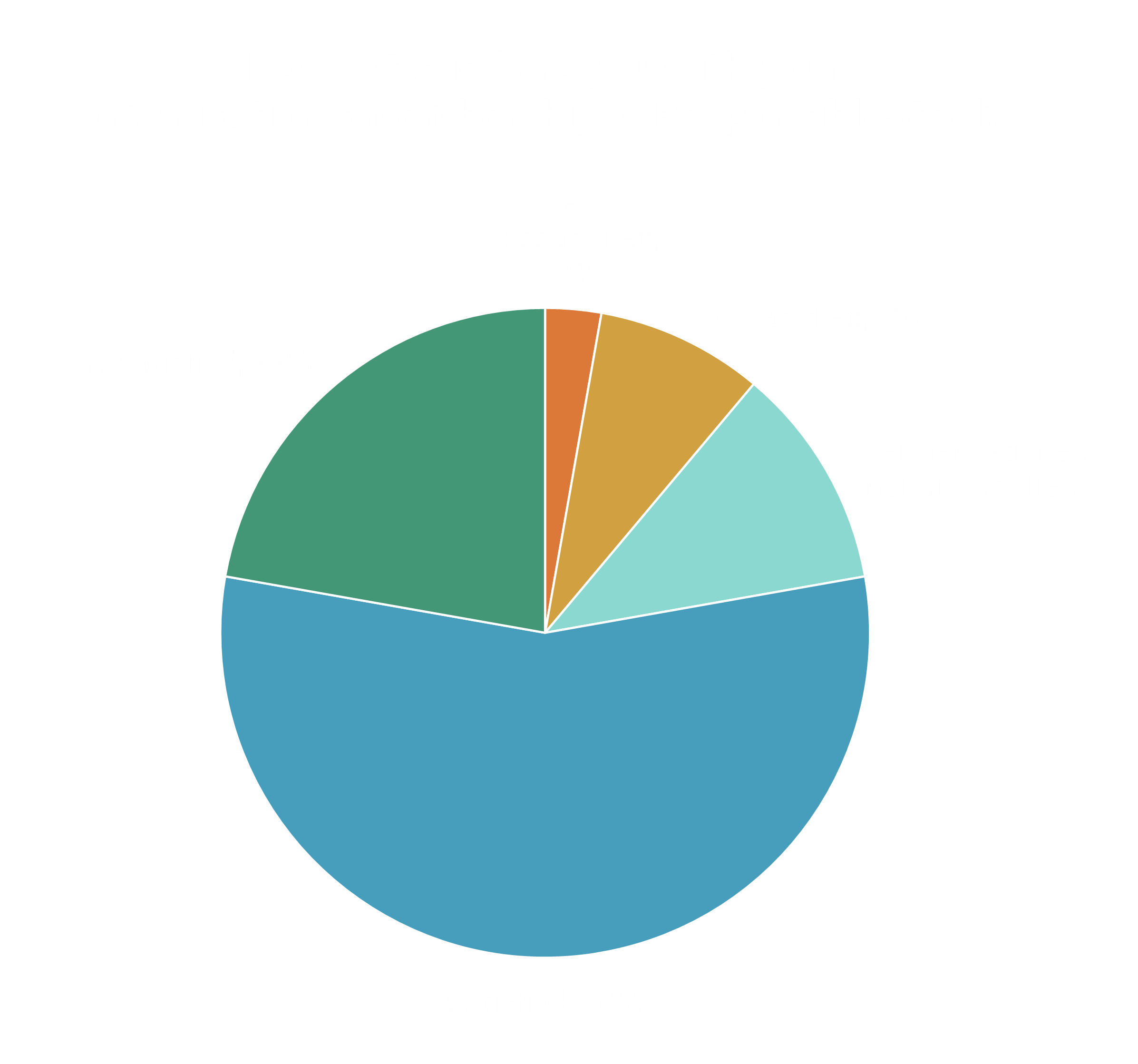

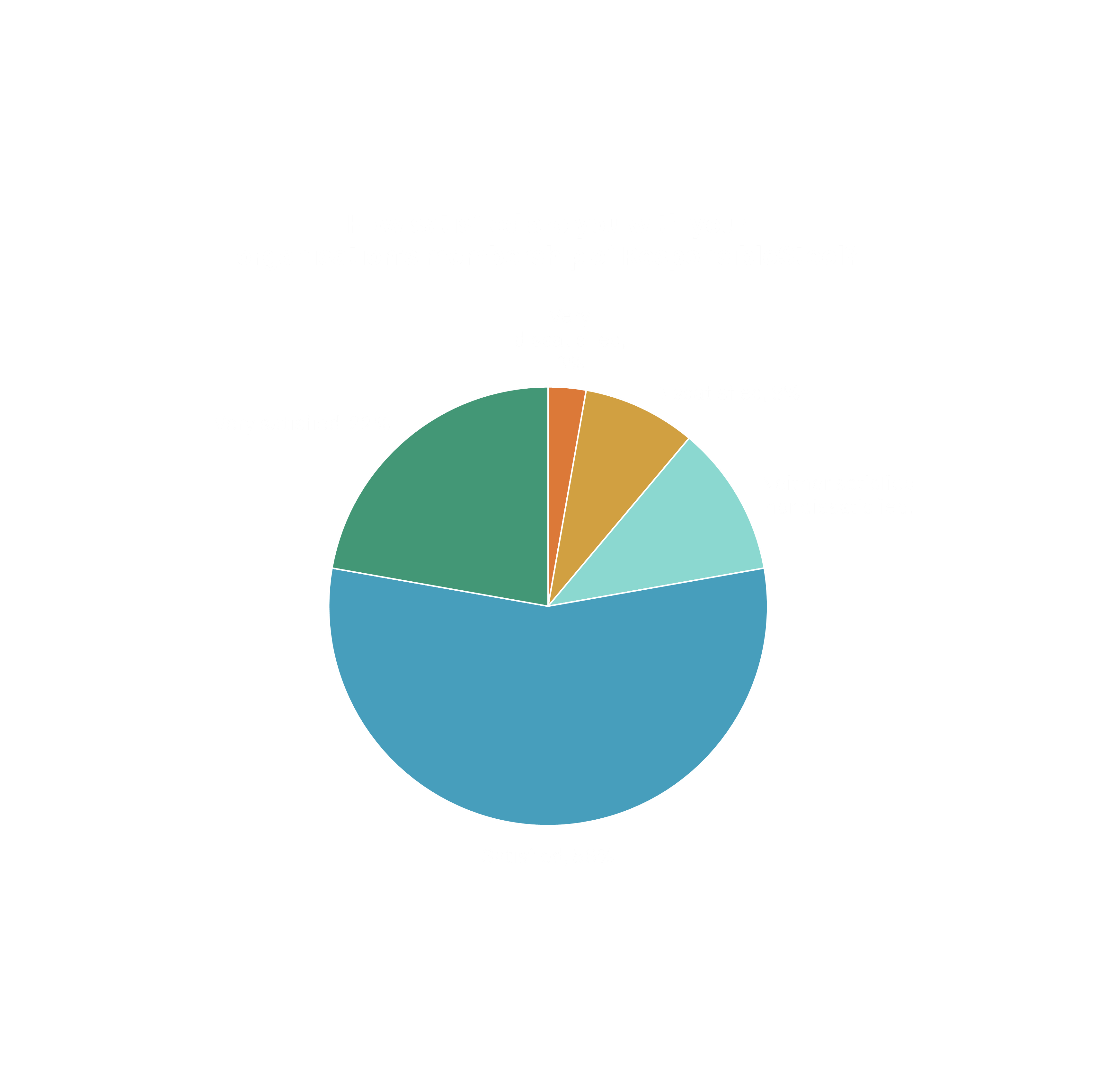

We have members headquartered in

37 countries.

Asia

Europe

Middle East

North America

Oceania

South America

We launched our inaugural annual membership survey in 2024 to ascertain the satisfaction levels of our members with their membership and to identify areas for improvement.

78% of the responses from members indicated that they were ‘satisfied’ or ‘very satisfied’ with ResponsibleSteel membership while only 11% said they were 'dissatisfied' or 'very dissatisfied.'

The key area for improvement requested by members was a greater opportunity for members to connect, both in-person and online, to network with each other, learn and share knowledge.

The greatest challenge members are facing is the lack of availability of low and near-zero emissions steel. Members also expressed difficulties in communicating about the commercial value of sustainability in steel and the complexity and changing nature of the standards landscape.

We launched our inaugural annual member survey in 2024 to ascertain the satisfaction levels of our members with their membership and to identify areas for improvement.

78% of the responses from members indicated that they were ‘satisfied’ or ‘very satisfied’ with ResponsibleSteel membership while only 11% said they were 'dissatisfied' or 'very dissatisfied.'

The key area for improvement requested by members was a greater opportunity for members to connect, both in-person and online, to network with each other, learn and share knowledge.

The greatest challenge members are facing is the lack of availability of low and near-zero emissions steel. Members also expressed difficulties in communicating about the commercial value of sustainability in steel and the complexity and changing nature of the standards landscape.

Actions we're taking

We're focused on delivering value to our members. To this end, we're expanding our member tools and opportunities for engagement. This includes work on:

1. A varied events programme for 2025/26, including in-person and online events.

2. A new account management system to ensure ResponsibleSteel is listening to members and adjusting approaches where necessary.

3. Stakeholder mapping and value propositions work to better target our key audiences and further develop our value offering.

4. A suite of tools to help explain the value of ResponsibleSteel certification, including further guides, case studies, and a campaign aimed at buyers and investors to increase demand.

Building cross-sector collaboration

Connecting the value chain

In 2024, ResponsibleSteel continued to strengthen partnerships with players across industry, policy and finance to accelerate progress and create a market for responsibly produced low emissions and near-zero steel.

Building a cohesive system

A globally interoperable system is essential to ensuring markets for low emissions steel can flourish. ResponsibleSteel was a leading voice in driving this work in 2024, collaborating with the 60+ signatories of the Steel Standards Principles, the International Energy Agency, and the Climate Club, and working with several initiatives seeking to reflect ResponsibleSteel’s system of embodied GHG measurement and Decarbonisation Progress Levels within their own frameworks.

We also made inroads at the national level. We welcomed the German Steel Association (WV Stahl) into membership and continued to build relationships with associations and policymakers in India and China. And in the US, ResponsibleSteel’s Progress Level 4 was identified as a benchmark for measuring and defining near-zero steel in the Modern Steel Act.

Engaging with investors

ResponsibleSteel's Finance Working Group brought together banks and investors in 2024 to discuss how the Production Standard can provide a framework of common indicators for sustainability performance and reduce risk across steel investment portfolios. We also began work on a campaign targeted at steel investors to demonstrate the value of Certified Steel in managing risk in steel portfolios and helping to meet reporting requirements. Keep an eye out for this in the coming months and share the guidance with your stakeholders.

Driving global demand

ResponsibleSteel and SteelZero collaborated last year on a series of webinars for ResponsibleSteel and SteelZero members to demonstrate how we're working together to mobilise buyers to drive the production of lower emissions steel.

Our forthcoming campaign will also target steel buyers as well as investors, demonstrating how Certified Steel can support buyers in meeting their net-zero targets, mitigate supply chain risks and meet regulatory requirements.

Ensuring a just transition

Last year, ResponsibleSteel and the Initiative for Responsible Mining Assurance (IRMA) launched a joint project to better understand the social impacts of the net-zero transition and how standards can help guide good practice.

With funding from the ISEAL Innovations Fund, which is supported by the Swiss State Secretariat for Economic Affairs SECO, the project aims to understand the role standards can play and establish a framework to ensure a socially responsible transition in the steel and mining sectors. Read our recent Q&A to find out more.

"We are proud to be supporting ResponsibleSteel as they ramp up their efforts to collaborate with policymakers and investors, ensuring that the critical levers are in place to accelerate steel's transition to near zero. Their proactive engagement with key stakeholders across industry, government, and finance is paving the way for a greener, more responsible steel industry."

Maria Mendiluce

CEO, We Mean Business Coalition

Message from the CEO

ResponsibleSteel and its members clearly made good progress in 2025. Yet the industry also faced undoubtable challenges in making tangible progress towards near-zero steel. Most evident are the delays in deep investments into low emissions technology across markets. Further variations in the definitions of ‘green steel’, often lacking the support of a multistakeholder approach, continue to create uncertainty. Yet this is precisely the time when we need to strengthen the systems we have built and ramp up climate action. ResponsibleSteel’s efforts to provide the necessary tools are stronger than ever.

I am inspired by the determination of many to drive genuine progress.

We’ve seen policymakers mobilise to tackle barriers to the industry’s transition; new forms of collaborative finance emerge to support change; steel buyers determined to send a signal to their suppliers; civil society calling for greater accountability; and progress on new technologies and development projects for green iron. I’m proud to count many of these change-makers among ResponsibleSteel's membership.

We are now entering a new era of progress. In 2025, we are working with members and partners to build the ecosystem to support a positive transition, and we welcome your participation in our working groups, events and other collaborative initiatives.

This includes work on effective policy drivers; actionable demand signals; the evolution of standards to drive a just transition; interoperability between standards to support markets for low emissions steel; and outreach to investors. My thanks go to our funders and partners who enable us to undertake this work: the Pooled Fund on Energy, Ceres, the Climate Group, ISEAL, IRMA and We Mean Business Coalition.

We are building important momentum. And providing the industry with the tools to navigate risks. As we navigate the uncertainties ahead, I look forward to collaborating with you further to build alignment, integrity and stability in the standards that will drive a responsible transition. Thank you for your continued support.

Annie Heaton

CEO, ResponsibleSteel

Message from the CEO

Annie Heaton

CEO, ResponsibleSteel

ResponsibleSteel and its members clearly made good progress in 2025. Yet the industry also faced undoubtable challenges in making tangible progress towards near-zero steel. Most evident are the delays in deep investments into low emissions technology across markets. Further variations in the definitions of ‘green steel’, often lacking the support of a multistakeholder approach, continue to create uncertainty. Yet this is precisely the time when we need to strengthen the systems we have built and ramp up climate action. ResponsibleSteel’s efforts to provide the necessary tools are stronger than ever.

I am inspired by the determination of many to drive genuine progress.

We’ve seen policymakers mobilise to tackle barriers to the industry’s transition; new forms of collaborative finance emerge to support change; steel buyers determined to send a signal to their suppliers; civil society calling for greater accountability; and progress on new technologies and development projects for green iron. I’m proud to count many of these change-makers among ResponsibleSteel's membership.

We are now entering a new era of progress. In 2025, we are working with members and partners to build the ecosystem to support a positive transition, and we welcome your participation in our working groups, events and other collaborative initiatives.

This includes work on effective policy drivers; actionable demand signals; the evolution of standards to drive a just transition; interoperability between standards to support markets for low emissions steel; and outreach to investors. My thanks go to our funders and partners who enable us to undertake this work: the Pooled Fund on Energy, Ceres, the Climate Group, ISEAL, IRMA and We Mean Business Coalition.

We are building important momentum. And providing the industry with the tools to navigate risks. As we navigate the uncertainties ahead, I look forward to collaborating with you further to build alignment, integrity and stability in the standards that will drive a responsible transition. Thank you for your continued support.

Come with us

Find out more about how you can support us:

Want to download this report?

Additional information:

Image credits: Acciai Speciali Terni / ArcelorMittal / Big River Steel / BlueScope / Shutterstock / SIJ /